Case Study: Predictive Inventory Management System for Retail

About Project

A manufacturing company that depends on the operation of a large group of industrial machines for their production processes. Unplanned equipment failure downtime that results in slowed production, higher maintenance costs, and reduced overall effectiveness is a serious problem. In the future, predictive maintenance using AI and machine learning is planned by the company to detect any potential failures before they occur along with the scheduling of maintenance. They are developing and deploying this solution with the help of Silverspace Inc.

Key Challenges

A large retail chain with multiple stores across regions faces challenges in optimizing inventory levels. The existing inventory management system relies heavily on manual forecasting and ordering processes, leading to frequent stockouts, overstock situations, and suboptimal shelf availability. This inefficiency not only impacts customer satisfaction but also increases operational costs due to excess inventory and expedited shipping.

Optimize Inventory Levels

Reduce instances of stockouts and overstock situations while maintaining adequate product availability.

Improve Forecast Accuracy

Implement a more accurate forecasting model to predict demand at a granular level.

Automate Replenishment

Introduce automation in inventory replenishment to streamline operations and reduce manual effort.

Solution Approach

The solution involves developing a predictive inventory management system using AI/ML techniques. Here’s how we approach solving the problem:

1.Data Collection and Preparation:

- Data Sources: Gather historical sales data from all retail stores, including SKU-level transactions, seasonal trends, promotions, and external factors (e.g., weather data, economic indicators).

- Data Cleaning: Clean and preprocess the data to handle missing values, outliers, and inconsistencies.

- Feature Engineering: Create relevant features such as seasonality indicators, day-of-week effects, and lagged sales data to capture patterns and trends.

2.Model Selection and Training:

- Demand Forecasting Models: Evaluate different time-series forecasting models such as ARIMA, Exponential Smoothing, and advanced machine learning models like LSTM (Long Short-Term Memory) networks.

- Model Training: Train models on historical data, validate performance using cross-validation techniques, and select the best-performing model based on accuracy metrics (e.g., MAE, RMSE).

3.Implementation of AI/ML Models:

- Integration: Implement the selected model into the inventory management system.

- Real-time Updates: Ensure the system can handle real-time data updates and adjustments to forecasts based on incoming sales dat

4.Automated Replenishment System:

- Decision Support System: Develop a decision support system that generates optimal reorder points and quantities based on predicted demand, desired service levels, and lead times.

- Integration with ERP: Integrate with the existing ERP (Enterprise Resource Planning) system to automate purchase orders and replenishment processes.

5.Monitoring and Evaluation:

- Performance Metrics: Define KPIs (Key Performance Indicators) such as inventory turnover rate, service level, and forecast accuracy.

- Continuous Improvement: Monitor system performance regularly, gather feedback from store managers, and refine models as needed to improve accuracy and efficiency.

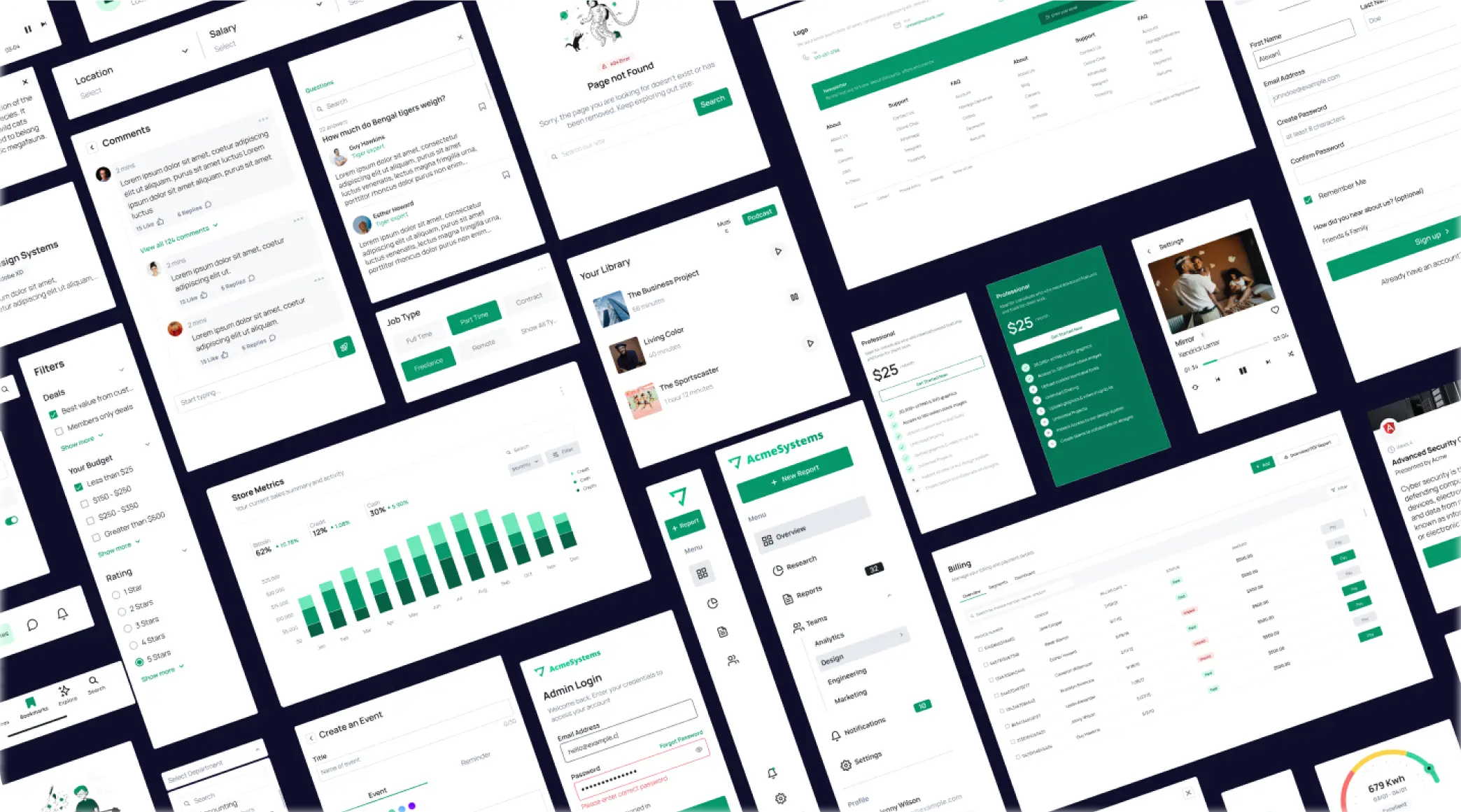

UI/UX

Key Results

Improved Inventory Management

Cost Savings

Operational Efficiency

Customer Satisfaction

What Our Clients Say

Silverspace Inc started handling our equipment maintenance and the transformation has been unreal. The AI-powered predictive maintenance solution has made a big difference in our operational efficiency and reduced downtime in the plant. The information and tools shared have been crucial for us to improve our production planning and extend our equipment's life.

John M Manufacturing Co